Product Introduction

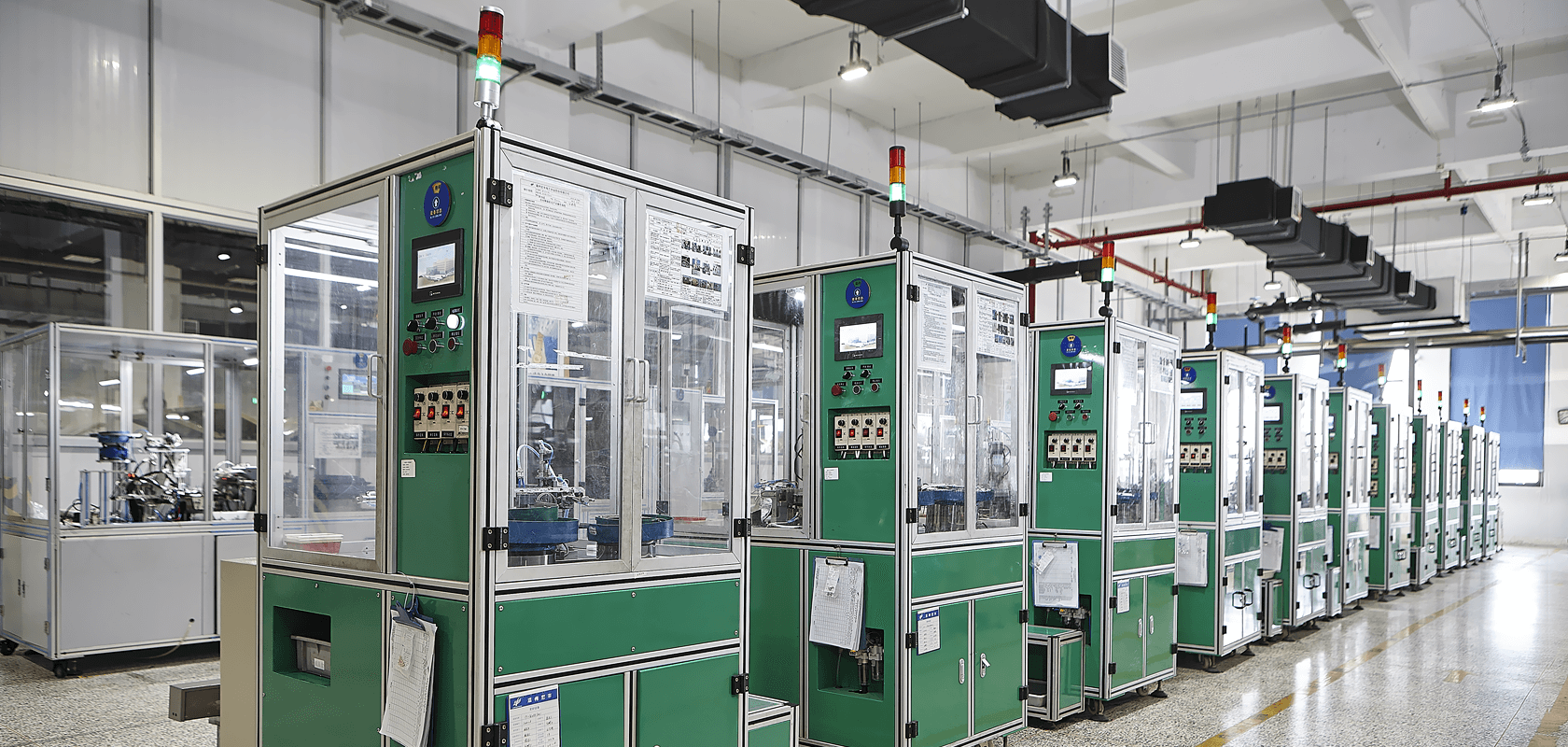

Centering on the integration of industrial chains, the Company actively expands the automatic processing capacity, independently develops intelligent equipment, realizes digital intelligent manufacturing of material processing and material application through material scheme design, improves the consistency and stability of product quality, saves energy and reduces carbon, and promotes high-quality development. According to the processing characteristics of industry products, the Company develops customized intelligent equipment such as combined molds and integrated punching and welding production lines to realize remote digital management and control.

Product Classification

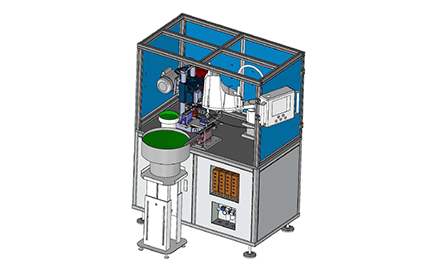

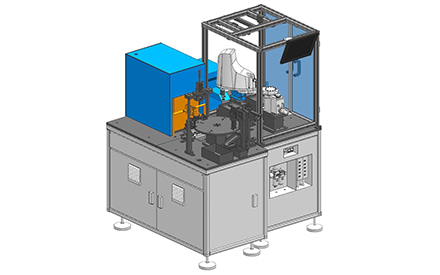

Intelligent Riveting Machine

Special feeding devices are used to send copper parts and silver points into riveting positions for riveting processing, realize fully automatic production, save manpower and production cycle, and guarantee stable and consistent product quality.

According to the types of the fed materials, it can be classified as linear machine, rotary machine and robot flexible machine.

The equipment has diversified functions that can support remote communication and can realize real-time monitoring.

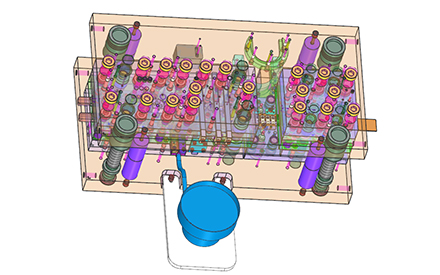

In-die Riveting Machine

Integrate die and riveting molds to realize synchronization of blanking and riveting of copper parts and further optimize the production. It can provide integrated manufacturing of product components in multiple combination forms such as in-die riveting, in-die riveting + tapping, and provide key equipment support for mass production and high-quality production.

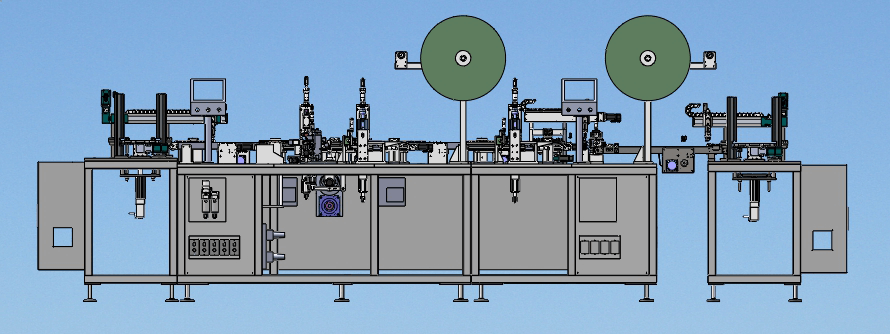

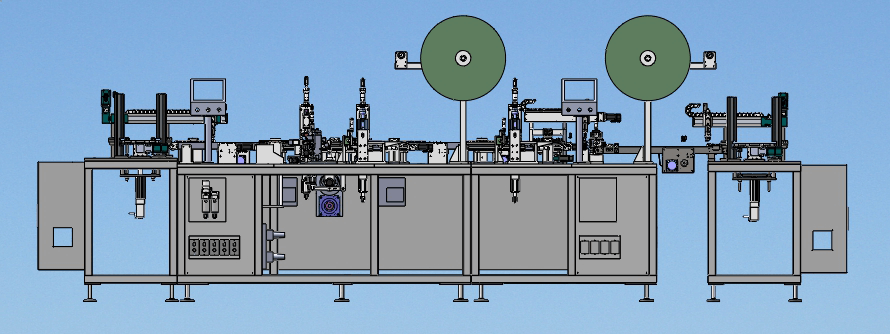

Intelligent Welding Machine

Copper belts or copper parts or silver points are sent to the welding station through special feeding device to replace manual swing welding and realize fully automatic production. The product quality is stable, and it can realize one worker multiple machines and save the labor cost.

Energy storage welding, resistance welding, induction welding or other welding methods can be selected according to the product features. According to the types of the fed materials, it can be classified as linear machine, rotary machine and robot flexible machine.

The equipment has diversified functions that can support remote communication and can realize real-time monitoring.